Featured Stories

Our facilities monitor energy efficiency and energy use, including electricity, steam and fuels. Facilities leverage local Energy Best Practice Teams to improve energy performance and initiate energy reduction projects. CPChem’s corporate energy team is composed of a representative from each facility’s local team, with a corporate team lead. This team shares best practices and successes while also establishing companywide energy goals.

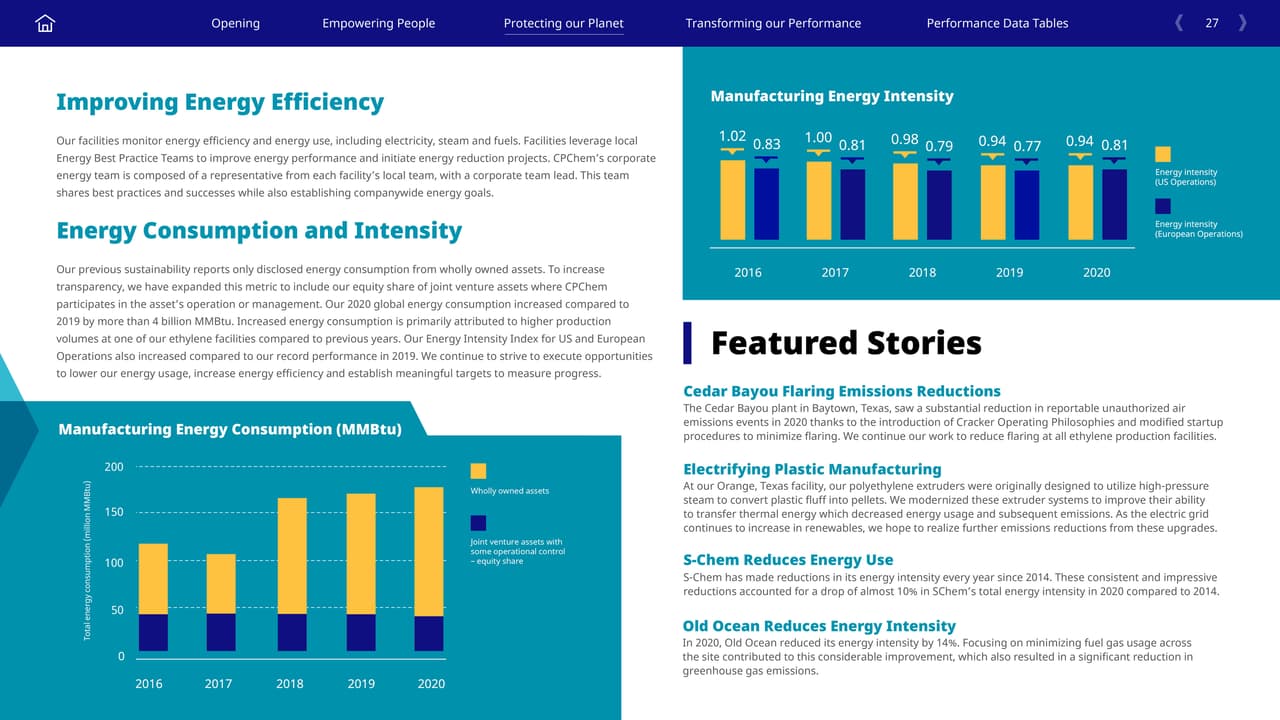

Our previous sustainability reports only disclosed energy consumption from wholly owned assets. To increase transparency, we have expanded this metric to include our equity share of joint venture assets where CPChem participates in the asset’s operation or management. Our 2020 global energy consumption increased compared to

2019 by more than 4 billion MMBtu. Increased energy consumption is primarily attributed to higher production

volumes at one of our ethylene facilities compared to previous years. Our Energy Intensity Index for U.S. and European Operations also increased compared to our record performance in 2019. We continue to strive to execute opportunities to lower our energy usage, increase energy efficiency and establish meaningful targets to measure progress.

Improving Energy Efficiency

Energy Consumption and Intensity

The Cedar Bayou plant in Baytown, Texas, saw a substantial reduction in reportable unauthorized air emissions events in 2020 thanks to the introduction of Cracker Operating Philosophies and modified startup procedures to minimize flaring. We continue our work to reduce flaring at all ethylene production facilities.

At our Orange, Texas facility, our polyethylene extruders were originally designed to utilize high-pressure steam to convert plastic fluff into pellets. We modernized these extruder systems to improve their ability to transfer thermal energy, which decreased energy usage and subsequent emissions. As the electric grid continues to increase in renewables, we hope to realize further emissions reductions from these upgrades.

S-Chem, a CPChem joint venture operation in Al Jubail, Saudi Arabia, has made reductions in its energy intensity every year since 2014. These consistent and impressive reductions accounted for a drop of almost 10% in

S-Chem’s total energy intensity in 2020 compared to 2014.

In 2020, our Old Ocean facility in Sweeny, Texas, reduced its energy intensity by 14%. Focusing on minimizing fuel gas usage across the site contributed to this considerable improvement, which also resulted in a significant reduction in greenhouse gas emissions.

Cedar Bayou Flaring Emissions Reductions

Electrifying Plastic Manufacturing

S-Chem Reduces Energy Use

Old Ocean Reduces Energy Intensity

Manufacturing Energy Consumption (MMBtu)

Manufacturing Energy Intensity

27